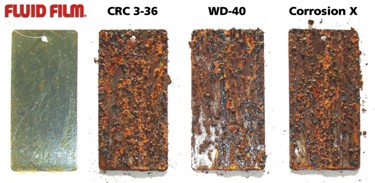

De resultaten van een recente onafhankelijke test waarbij enkele produkten, waaronder FLUID FILM, werden aangebracht op stukjes staal , die vervolgens gedurende 24 uur gedroogd werden, om dan gedurende 7 weken (1.176 uren zoals de ASTM B117 standaaren het voorschrijven) in een zout kabine te plaatsen, zijn duidelijk zichtbaar op de onderstaande afbeelding en spreken voor zich.

De grafiek hieronder is gebaseerd op door de fabrikant van FLUID FILM gepubliceerde informatie. Daarom is de informatie in verband met deze grafiek in het Engels. Onze excuses voor de mogelijke ongemakken dat dit zou veroorzaken.

_________________________________________________________________________________

Comparison of Fluid Film® Superior Lubicant, Penetrant, Rust & Corrosion Preventative to Seven (7) well known aerosols in todays marketplace.

THE BOTTOM LINE: FLUID FILM® GIVES 77.5% MORE USABLE PRODUCT !

Testing was performed in the laboratory of Eureka Chemical Company according to procedures similar to ASTM methods for measuring corrosion. For the test, each product was sprayed onto eight, 3X6" bare steel test panels. The panels were then suspended vertically for 24 hours to simulate end use conditions. After 24 hours, all products except Fluid Film® had sagged toward the botto edge of the panels, resulting in increased film thickness at the bottom and less thickness above. All of the panels were then suspended within a closed cabinet with a salt fog atmosphere of 5% salt concentration. The panels were removed from the chamber when each reached approximately 95% surface corrosion. Two product panels reached 95% corrosion within 14 days, a third in 45 days. After 52 days (1248 hours) Fluid Film® had reached a corrosion percentage of only 5%.

This comparison of corrosion protection demonstrates the long-term corrosion control economy of Fluid Film®. In addition, the surface adherence of its woolwax-based formula is self healing in cases of scoring or similar damage and it remainssoft and flexible, doe snot wash away or crack. Fluid Film® can be removed easily from most materials when required.

Fluid Film® is non-toxic and non-hazardous, both important considerations in workplace environment and safety. Once applied, Fluid Film's® flash point is a high 405°F, compared to typical 125°F for solvent-based products.